Hydrogen storage as an enabler for sustainable mobility

Hardly any other technology brings engineers and environmentalists together faster than hydrogen/fuel cell propulsion. After all, the vision of emission-free energy generation and use seems obvious: Theoretically, hydrogen can be produced by electrolysis with renewable energies without emissions and by-products. And even when the hydrogen is used in fuel cells, only water is produced in addition to electricity.

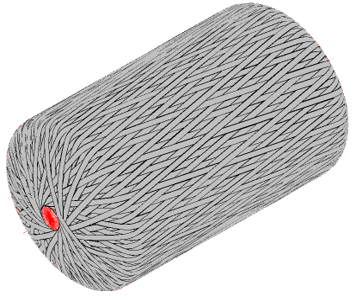

However, engineers still have a number of tasks to solve before hydrogen can be used in vehicles commercially. Especially the storage of hydrogen is challenging because it is the smallest existing molecule and therefore very difficult to store. Currently, storage for vehicles is carried out at up to 700 bar in pressure vessels. This is where carbon fibers show their strengths. No other material allows hydrogen to be stored at high pressures with such low system weight.

But since carbon fibers are expensive, the material must be applied wisely. Saving weight is also a clear necessity in terms of lightweight design and reduction of moving masses. Of course, the load-bearing capacity of the CFRP pressure tank must be ensured under all circumstances in all load situations.

Holistic development of CFRP Type IV pressure vessels

As a specialised engineering partner, CIKONI offers application-specific simulation models that meet the requirements of designing high pressure hydrogen vessels. Thereby, the FE simulation serves to clarify the following questions:

- Ensuring the load capacity and pressure resistance in all usage scenarios

- Geometry definition of the vessel and connection components

- Material selection and definition of hybrid material concepts

- Specification of the layer structure in the dome and shell area

- Implementation of production planning and feasibility studies

- Achievable power to weight ratio and material savings to reduce costs

- Resulting cost estimation

Of course, we also work with our customers beyond the simulation on upstream and downstream steps such as material characterization, testing and production planning. CIKONI also develops innovative CFRP high-pressure vessels, which achieve a higher installation space efficiency due to new production methods.

New simulation methods and virtual prototyping

Together with Altair, Crescent Consultants Ltd. (UK) and other partners, CIKONI has now further optimised the accuracy of its simulation models. Using a multiscale approach, the material is first characterized virtually using micro-model approaches and then transferred to the macro-models. Thereby, specific characteristics of the winding, such as the overlap in the dome area or the discontinuous fibre volume content can be better represented.

Thus, a faster development is possible because time-critical material characterizations (so-called “coupon tests”) are reduced and the quality of the simulation is increased. But also the production itself can be better represented and transferred into the model by special methods.

Details can be found in a current customer success story together with our partner Altair, which you can download here: Towards Efficient Composite Pressure Vessel Design (pdf).

Interested to learn more and cooperate with CIKONI too? Get in touch.

[wpforms id=”1478″ title=”false” description=”false”]

Sources

- Altair: Towards efficient Composite Pressure Vessel Design, June 2020