Hydrogen Storage is Key

In the quest for sustainable energy solutions, hydrogen pressure vessels represent a significant leap forward. CIKONI, a pioneer in composite materials engineering and lightweight design, is leading this revolution. With our groundbreaking advancements in hydrogen pressure vessel technologies, we’re setting new industry standards for safety, efficiency, and cost-effectiveness.

Hydrogen energy is at the forefront of the renewable energy transition. At CIKONI, we offer a comprehensive suite of services to revolutionize high-pressure storage systems. Our approach starts from the ground up, encompassing concept development, rigorous material testing, and feasibility studies, ensuring every solution is tailored for optimal performance and safety.

” Our dedication to CFRP technology underscores CIKONI’s commitment to advancing sustainable energy. This focus is central to our efforts in pioneering efficient, future-ready solutions. “

Dr. Jan-Philipp fuhr, Managing Partner at CIKONI

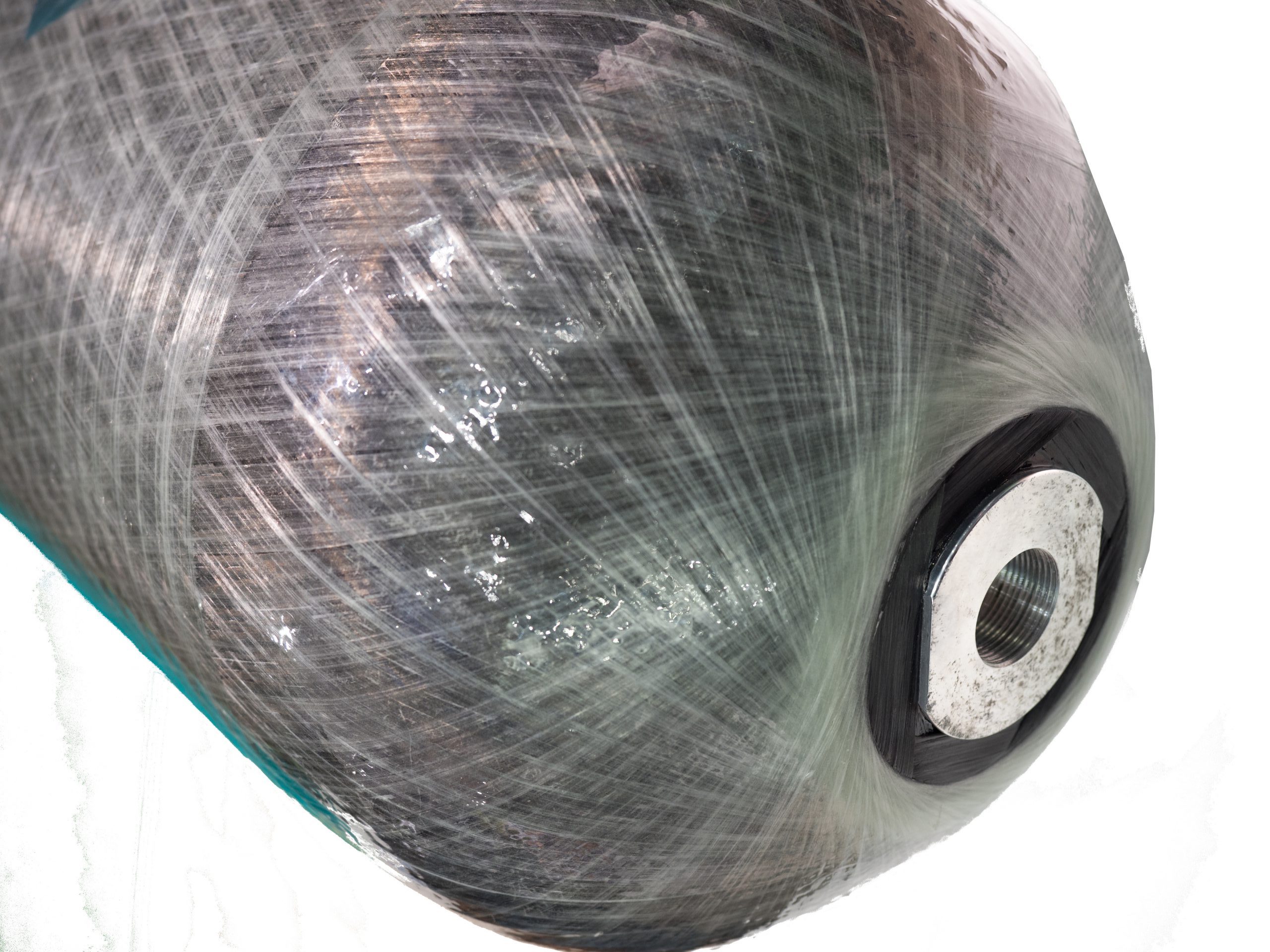

The CIKONI Edge: Carbon Fiber Engineering for Superior Pressure Vessels

Our expertise doesn’t stop at design; it extends to the very fabric of our pressure vessels. Utilizing cutting-edge carbon fiber engineering, we develop complete systems that include everything from liners to add-on components. Through advanced winding simulation and structural simulation transfer, we optimize manufacturing processes and the layer structure of pressure vessels, embodying the pinnacle of lightweight design.

Innovative Manufacturing Processes

Our commitment to innovation shines through our manufacturing capabilities. With proprietary robotic winding equipment and a range of processes like wet winding and towpreg winding, CIKONI is at the vanguard of producing next-generation hydrogen pressure vessels. This not only meets the rising demand for sustainable energy solutions but also highlights our dedication to versatile and innovative composite materials engineering.

Ensuring Quality with Advanced Robotics

Quality assurance is paramount, and our robot-based in-line inspection systems set industry benchmarks. This technology provides continuous, automated monitoring, enhancing both product safety and manufacturing stability. It’s how we ensure our hydrogen pressure vessels not only meet but exceed global standards.

Collaborative Development from Prototype to Production

At CIKONI, collaboration is key. Our comprehensive service range includes support for both prototypes and series production, enabling effective scaling of operations. Through close collaboration, each project benefits from our award-winning expertise in composite materials and lightweight engineering, from concept to manufacturing.

As we continue to push the boundaries of hydrogen storage technology, our vision remains clear: to contribute to a sustainable, energy-efficient future. Our investments in technology and process innovation reflect our commitment to this cause and our belief in the transformative power of hydrogen energy.

To learn more about how CIKONI is revolutionizing hydrogen pressure vessel technologies and driving advancements in carbon fiber engineering, visit our website. Join us in our journey toward sustainable energy solutions, where innovation meets excellence.

Conclusion

The development of hydrogen pressure vessels is more than a technical achievement; it’s a step towards a sustainable future. With CIKONI’s expertise in composite materials, carbon fiber engineering, and lightweight design, we are not just engineering solutions; we’re shaping the future of energy.

For further details on CIKONI’s innovative solutions and services in composite materials engineering, visit CIKONI’s official website.