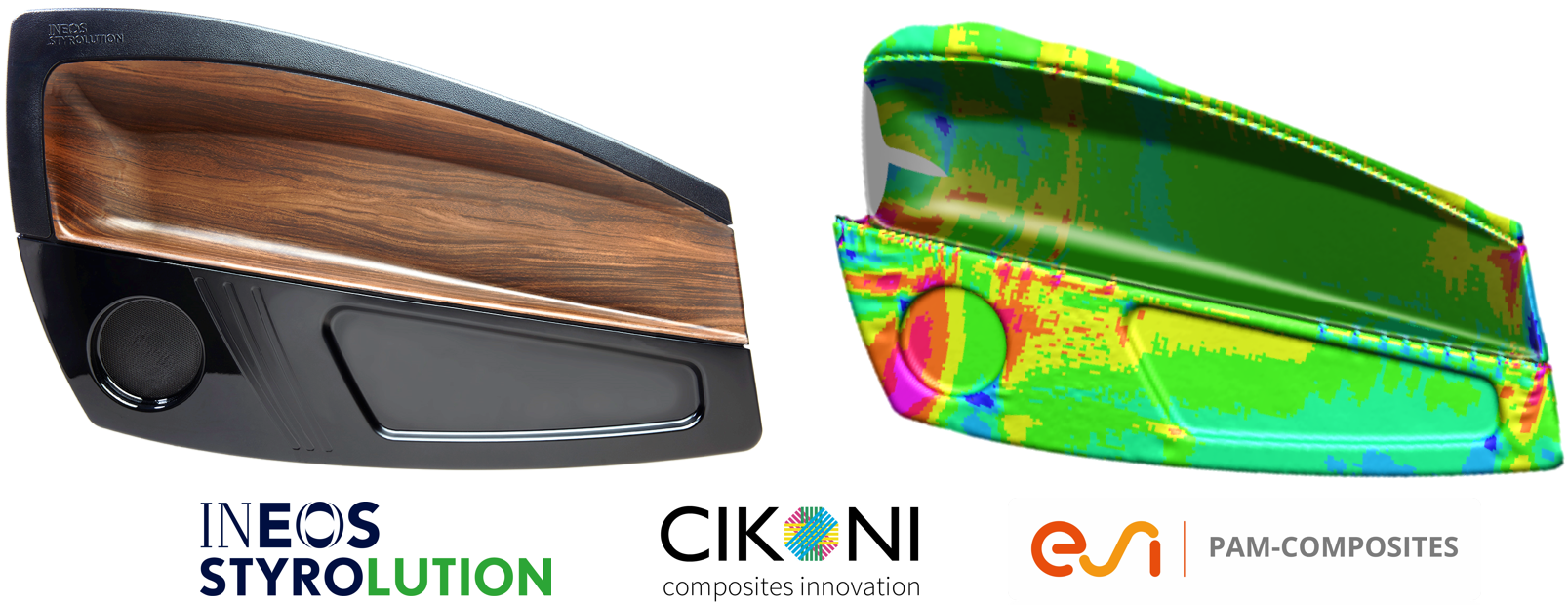

INEOS Styrolution presented last October at the K-Messe 2016 in Düsseldorf, Germany an innovative thermoplastic organic sheet for the manufacture of continuous fiber reinforced composite components. StyLight is the first and only thermoplastic composite material created from a styrene foam Styrene-acrylonitrile (SAN) matrix and various Glass Fiber and Carbon Fiber reinforcement textiles. The processing and molding is carried out in a similar way to other organic sheets on the market, but there are distinct advantages to this material. For example, the extremely low shrinkage and the gloss of the SAN matrix contribute to the outstanding off-tool quality of the surface that can be varnished without further processing.

In support of this product launch, INEOS Styrolution is entering into a partnership with CIKONI and ESI, to ensure the availability of the necessary methods and tools for the virtual design of components. The objective of this partnership is to guarantee customer-specific feasibility studies can be delivered early on. The technology demonstrated at the K-Messe 2016 was analyzed with ESI software for composites manufacturing simulation and virtual crash testing (PAM-COMPOSITES and Virtual Performance Solution), within the framework of a pilot project. The material characterization carried out by CIKONI for the reshaping and structural simulation confirms the outstanding features of this new material. The structural characteristics are optimal and demonstrate a surprisingly low level of scattering even with matrix-dominant shear tests.

CIKONI, headquartered in Stuttgart, Germany, is a development partner for customers in the automotive, aviation, and consumer goods industry, and specializes in lightweight construction and fiber composite technology. CIKONI meets customer requirements both in the serial application of new materials and in the tools and processes needed to evaluate the potential of such materials in the early phases of product development.

Contact

Please feel free to contact us for further informations regarding innovative lightweight strategies:

[wpforms id=”1475″ title=”false” description=”false”]