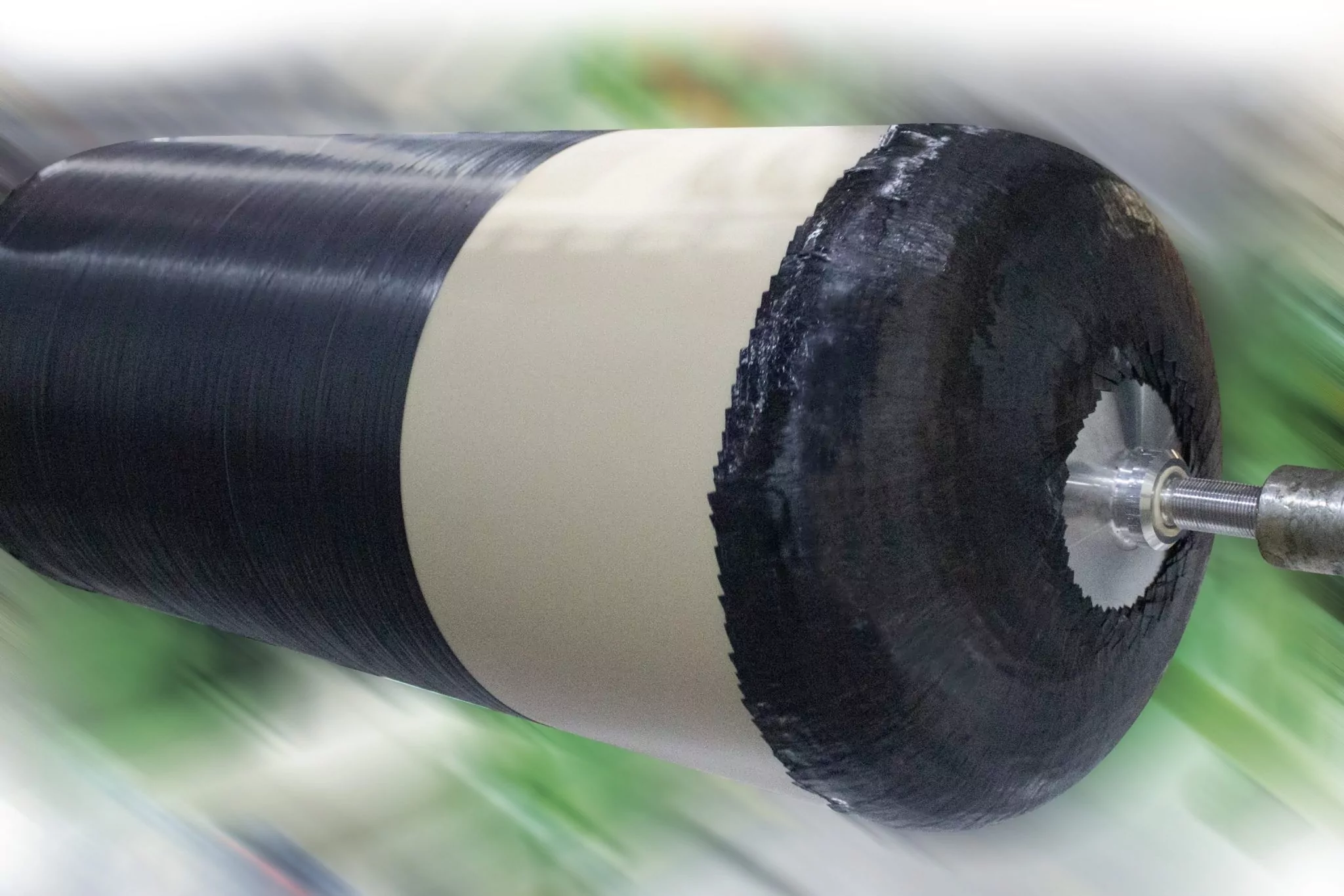

Composite pressure vessels (COPVs) are at the heart of modern lightweight storage solutions for hydrogen and other high-pressure applications. While the cylindrical section often dominates the visual appearance, the dome regions define efficiency, safety, and overall performance. Weight, material consumption, and usable storage volume are strongly influenced by how domes are designed and reinforced.

At CIKONI, we specialize in engineering advanced composite solutions with a strong foundation in finite element (FE) simulation. By combining structural analysis, material modeling, and process know-how, we enable our partners to push the boundaries of COPV technology.

Why the Dome Matters

Unlike the cylindrical section, which is relatively uniform, the domes experience complex stress distributions under pressure load. Traditional winding techniques often lead to material inefficiencies and over-dimensioned laminate structures in these areas. This results in higher fiber consumption, increased cost, and unused lightweight potential.

Targeted dome reinforcements can address these challenges – but only if they are designed and validated with precision.

Simulation-Driven Engineering at CIKONI

CIKONI’s advanced FE simulation workflows for composite pressure vessels provide the capability to:

- Accurately model anisotropic material behavior of fiber-reinforced laminates

- Predict stress distributions, interlaminar shear effects, and failure modes in dome regions

- Optimize laminate architecture and reinforcement strategies before physical prototyping

- Couple virtual prototyping with realistic manufacturing constraints and process parameters

By applying this simulation-driven approach, we create designs that are both mechanically robust and resource-efficient.

Automated Dome Reinforcement with Fiber Patch Placement (FPP)

In collaboration with Cevotec and Roth Composite Machinery, these engineering insights are transformed into industrial practice. Using Fiber Patch Placement (FPP), reinforcement patches are placed with high accuracy directly on the liner, guided by the optimized laminate design.

The benefits are clear:

- Up to 15% carbon fiber savings compared to conventional winding

- Improved CO₂ footprint through material efficiency

- Increased storage capacity within the same installation space

- A scalable, automated process ready for industrialization

The process is supported by ARTIST STUDIO software and realized with the SAMBA Pro PV-1 machine, ensuring sensor-assisted, documented, and repeatable manufacturing.

Webinar Invitation

To share this validated approach, we are hosting a joint webinar with Cevotec and Roth Composite Machinery. Together, we will present how simulation-driven engineering, automation, and advanced FPP technology converge to define the next generation of COPVs.

Who should attend?

Engineers, production managers, and decision-makers in the composite and hydrogen sectors who want to learn how to combine simulation expertise with automation technologies to achieve measurable improvements in cost, weight, and performance.

Stay tuned for the official date and registration link – and join us to explore how dome reinforcements are unlocking new levels of efficiency in composite pressure vessel design and manufacturing.

Register here: COPV Dome Reinforcement Seminar