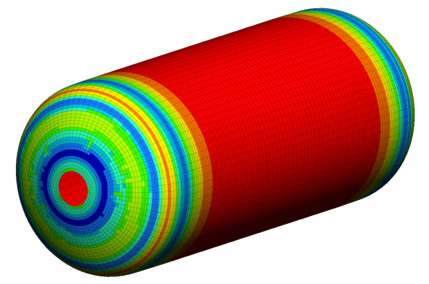

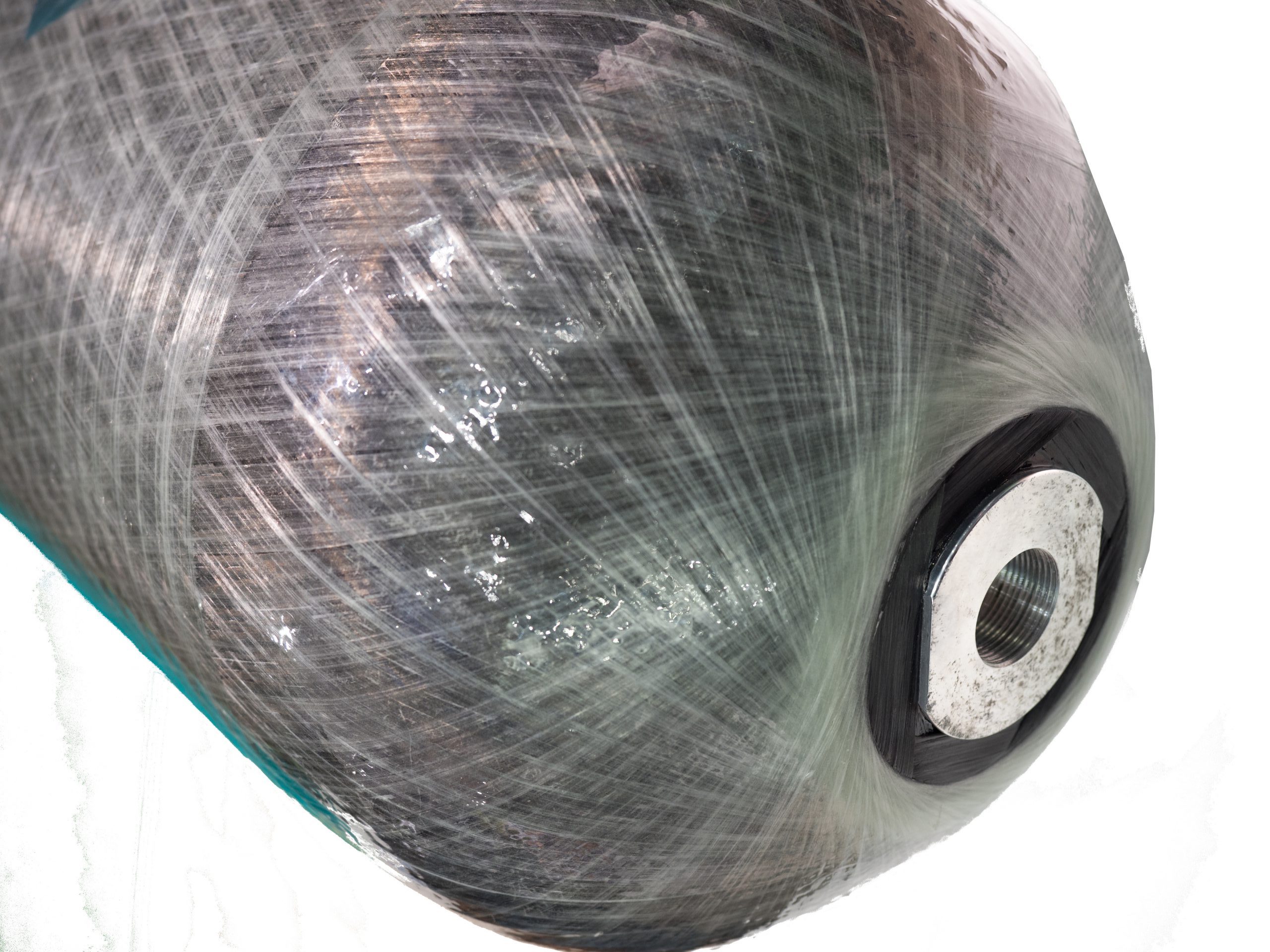

The reduction of testing and manufacturing costs is a major challenge in the development of a hydrogen pressure vessel. Therefore, we have created a design process using modern simulation technologies, which offers a significant reduction of risks in the development of composite pressure tanks. Our presentation at the Altair Technology Conference shows how we have combined concept, design, testing and process development into a chain.

Register here: https://web.altair.com/atcx-composites or find further information on the Development of H2-Pressure Vessels here.