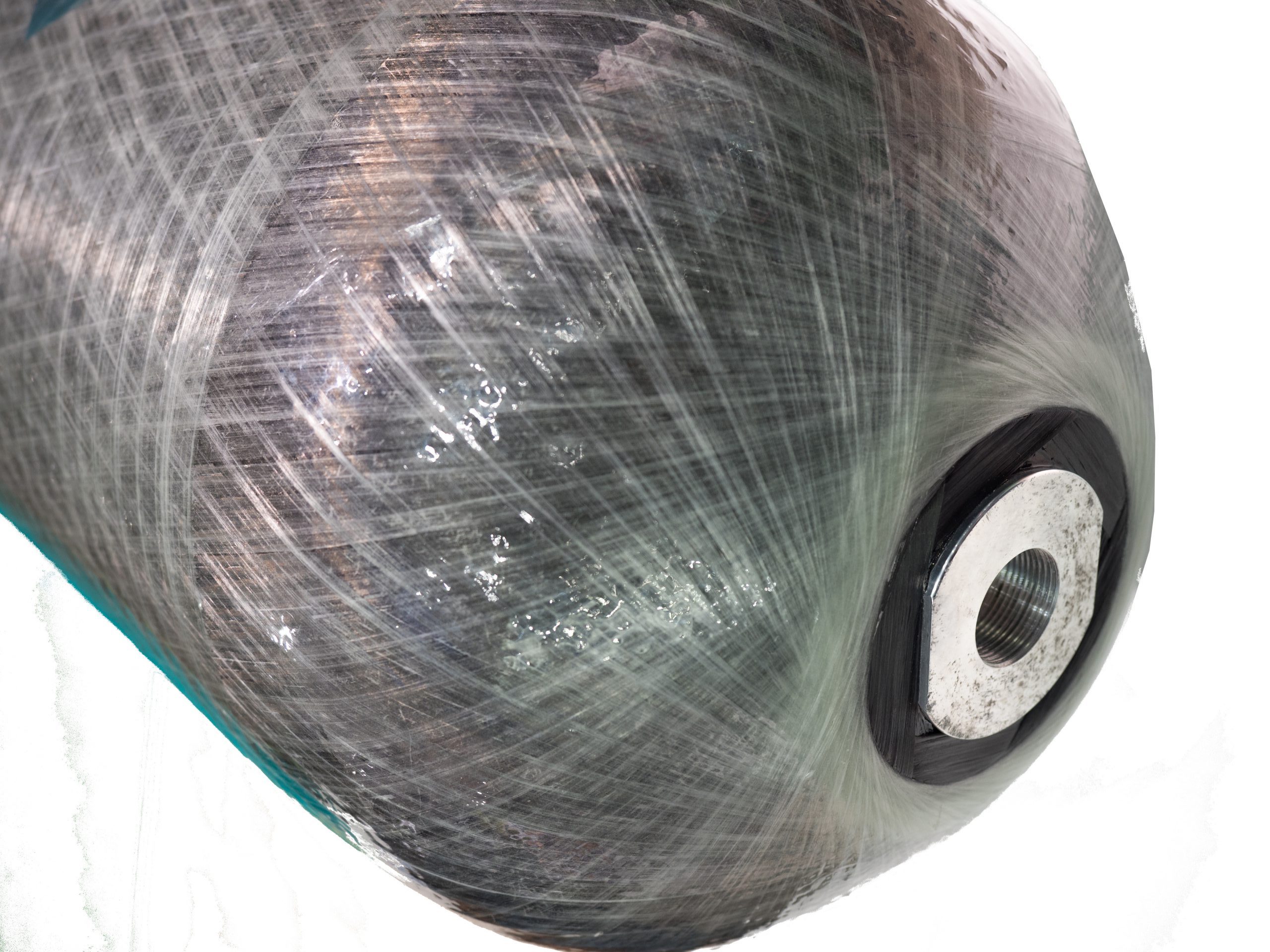

Metal Matrix Composites (MMC) offer superior performance at elevated temperatures. Especially Carbon fiber reinforced aluminium offers potential for an excellent performance to weight relationship. CIKONI GmbH is currently active in a research project that develops process simulation methods for squeeze-infiltration of aluminium matrix fiber composites to assess the textile interaction with the injected matrix. The greater goal is to increase the efficiency of the process development steps and gain better insights into effects of defects in manufacturing of MMCs.

The numerical prediction of the permeability of an orthogonally woven 3D textile is investigated using an ICFD solver. For this purpose, a mesoscopic unit cell is infiltrated and the permeability is determined using the relevant flow parameters. Due to the multi-scale nature of a reinforced fabric, the influence of fibre bundles on the flow permeability in the thickness direction is investigated in a parameter study. The model can efficiently be reduced to a quarter of its size by geometric considerations, which means a considerable saving of computation time. In a parameter study, even slight changes in geometry led to a deviation in permeability of up to 65%.

The investigations have shown that even small differences in fibre bundle porosity lead to a flow acceleration in a hexagonal unit cell. The virtual permeability prediction for orthogonal 3D fabrics shows high agreement with experimental measurements. For a 3D orthogonal mesh, the intra-laminar flow must be taken into account, highlighting the importance of simulative methods to assess the manufacturability of MMC components.

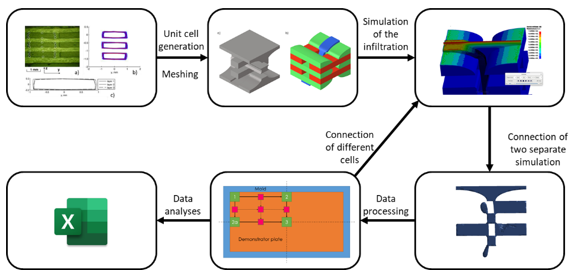

The matrix material flow is linked to the temperature to obtain a more realistic representation. A simulation methodology has been developed by CIKONI to map the infiltration of MMCs as a function of the relevant process parameters. Four representative unit cells are used, which are connected by a transfer of the boundary temperatures. In addition, a thermally saturated flow simulation and a coupled unsaturated infiltration simulation are formed per simulation series. The thermal conductivity perpendicular to the fibre axes required for the thermal simulation is determined for this purpose by means of a 2D simulation in the micro plane and compared with analytical formulae of similar geometries. A good agreement with an analytical formula is reached.

Another objective is to develop and apply a method to numerically predict the time required for the infiltration of a macroscopic demonstration plate with a metal matrix taking into account the mesoscopic unit cell geometry. Using the developed methodology, a simulative parameter study of the infiltration time is performed over the initial temperatures of the melt, mould and preform using the unit cell created. The results map the expected relationship between temperatures and infiltration time. With increasing initial temperatures, the infiltration rate also increases, whereby in the model numerically investigated in this work, the temperature of the melt has a greater influ-ence than that of the preform and the mould.

With the given results, CIKONI is capable to simulative the manufacturing process of MMC efficiently and optimize MMC-components for manufacturability without endless experimental iterations. If you have a pressing challenge in the field of composite materials, contact us today for a first discussion of possible solutions.