What is structural simulation of composites used for?

The main objective of structural simulation based on finite element analysis (FEA) is the prediction of the mechanical behavior of composite parts during virtual product development. Aspects can be the deformations under external loading, the damaging behavior or the dynamic response. The goal is to start into the prototyping stage already with an optimum design to minimize costs and development time caused by numerous design iterations and extensive testing. For lightweight applications, optimum means to fulfill the functional requirements with a minimum use of material.

Why is numerical simulation of composites challenging?

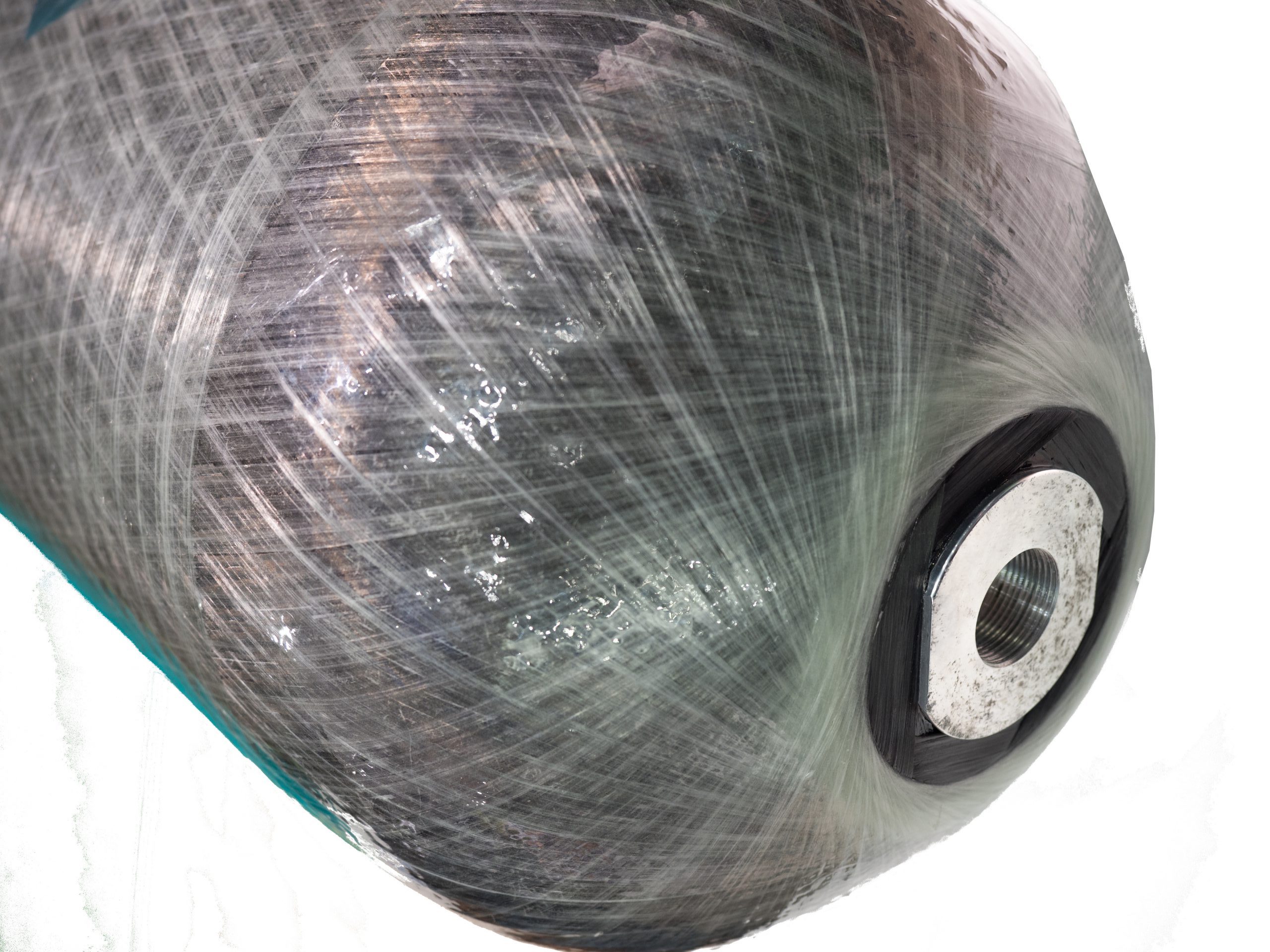

The predictive capability of composites simulation is strongly dependent on the validity of the applied numerical models. The nature of composite materials like CFRP, GFRP or AFRP causes a complex anisotropic behavior. Furthermore, especially failure mechanisms are governed by the type of fabric (weave, non-crimp fabric, braid …) and the matrix system used (thermoset, thermoplast …). This makes the selection of the appropriate modelling approach, the model identification and the evaluation of simulation results a task for experts.

Additionally, manufacturing effects have a strong impact on the actual mechanical properties of a composite part. Local variations of the fiber orientations caused by draping can induce significant knock-downs in stiffness and strength. Therefore, some of the key questions during composite part dimensioning are, if and how these influences have to be considered and which actions can be taken to reduce their impact on the final part performance.

What makes the approach of our engineers special?

Our roots are material mechanics, manufacturing technology and simulation of composites. We think and act interdisciplinary and thus find holistic and creative solutions which meet the requirements of composites to multiply your innovative capabilities. Base on our longtime experience with stiffness, strength and crash simulation of composites we support or advise you in all stages of structural part dimensioning.

Our expertise includes:

- Identification and validation of material cards for FE simulation with a focus on damage and failure criteria

- Planning, coordination and evaluation of test programs for material characterization

- Consideration of the as-built properties within structural simulation, e.g. by using fiber orientations from draping simulation or optical 3D preform analysis

- Numerical sensitivity studies on laminate and part level to evaluate tolerable limit values for manufacturing effects (limiting samples, quality criteria and fabrication tolerances)

- Laminate design and optimization by using advanced failure criteria and optimization algorithms

For your special tasks related to new materials, manufacturing processes or modelling approaches, we develop and validate simulation methods, customized tools or evaluation routines that fit seamless into your CAE process chain.

Some examples for typical questions of our customers:

- Lightweight potential: I want to design my product lighter by using carbon composites. How much weight reduction can I expect after consideration of all requirements from structural mechanics and manufacturing?

- Mechanical robustness: I use an optimized anisotropic laminate for my application. Which fabrication tolerances can be allowed for fiber layup or preforming without risks for the part performance?

- Material parameters: I need a material card for stiffness and strength simulation for a specific material system. Which failure models are suitable and which test program is required for model identification?

- Your simulation skills: Our Company plans to build up in-house composites simulation know-how for future projects. Can CIKONI experts support us?