Sometimes the more sophisticated design is the simpler one. After all, anyone familiar with the complex development and production processes of automotive components which look trivial on first sight, knows that a whole world is turning behind the smallest screw. The idea of integral component development and production to simplify supply chains, reduce assembly steps and realize lightweight design through functional integration is therefore just as obvious as highly important.

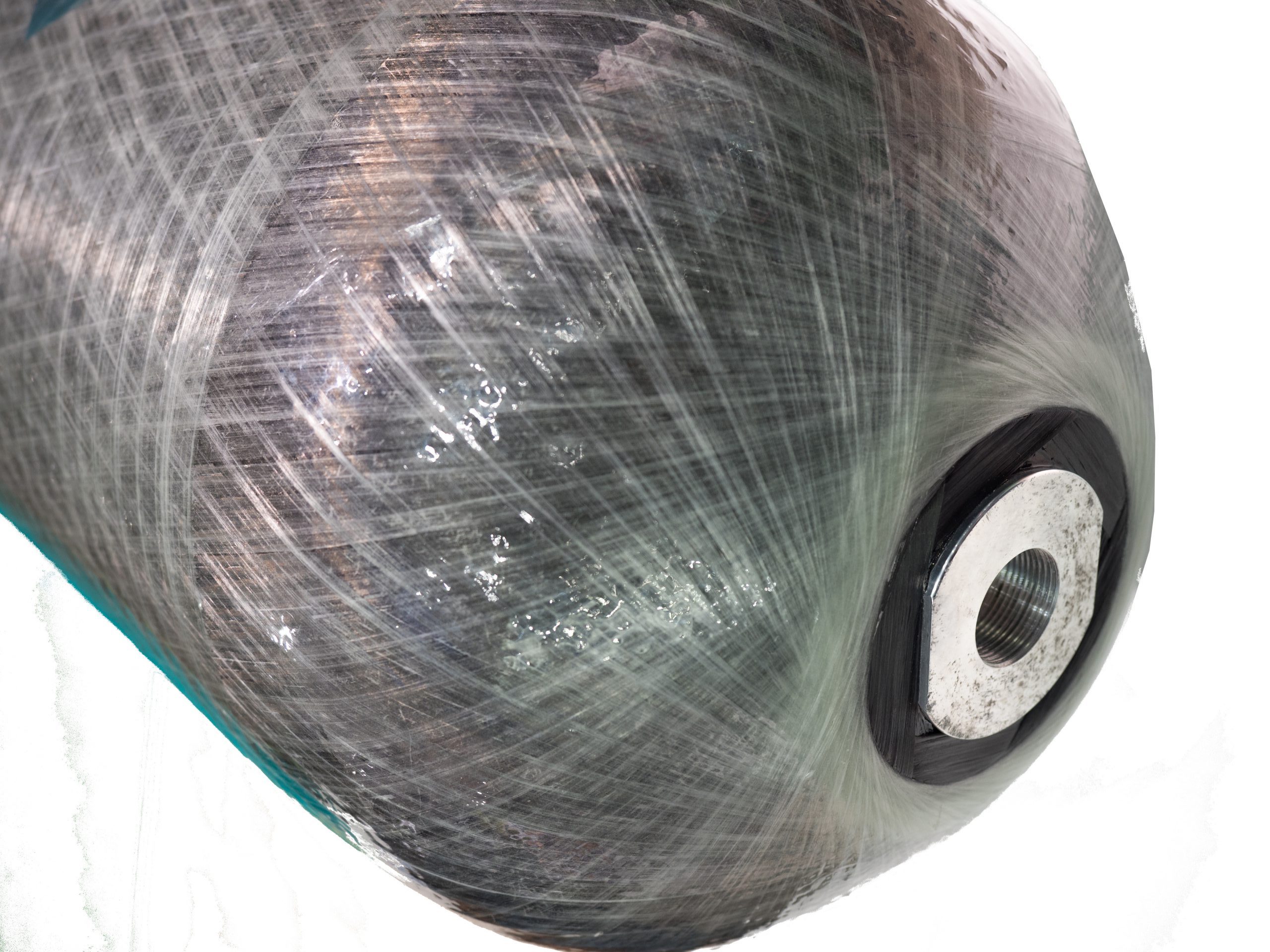

The digital development of components and their additive manufacturing meanwhile allows for concepts that until a few years ago would have been considered unthinkable by experts. This is driven by a rapid development of 3D printing technology with increasing production speeds, bigger dimensions and better mechanical properties.

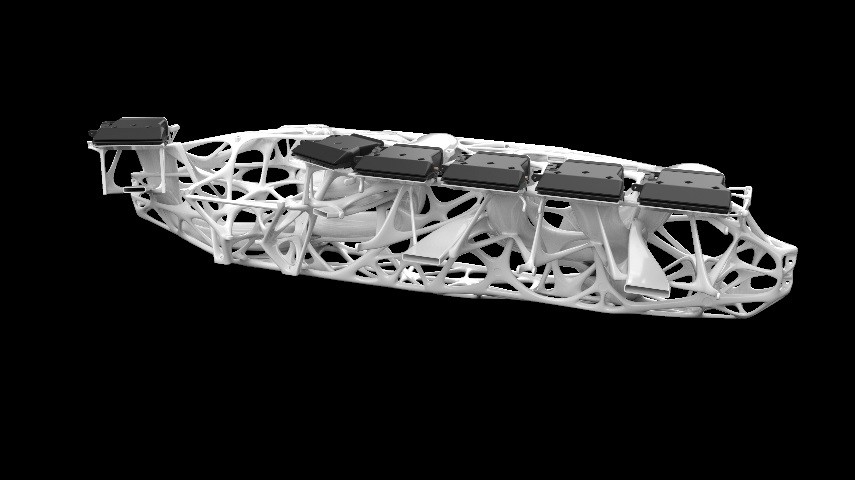

These methods are particularly interesting due to the consistent and early use of numerical topology optimization in component development. In this way, based on the available installation space, bionic structures are digitally created that ideally fulfill the dimensioning load cases and boundary conditions right from the start.

Stuttgart-based CIKONI GmbH has demonstrated this innovative development approach on behalf of SMP Deutschland GmbH based on a bionic support structure for instrument panels and was thus able to bring its expertise in numerical optimization, structural design and bionic design into the trailblazing project as a specialized development partner for hybrid lightweight design. One of the highlights of the technology demonstrator, which has consistently been created under close-to-production design premises, are the load-carrying air ducts, which, in addition to other functions, are integrated directly into the overall structure without additional assembly steps.

The additively manufactured cockpit carrier debuted at the CES 2018 in Las Vegas as part of the Empathic Cockpit by Motherson Innovations and also recently won the prestigious SPE Innovation Award 2018 in the Structural Components category. Once again CIKONI and SMP are providing innovative power in the field of automotive interior and exterior with an excellent sense for trends and future topics.

Video on the overall concept of the bionic carrier:

Links:

- Winner list of the SPE 2018 Automotive Award, Parts & Components

- The Empathic Cockpit at Motherson Innovation

Interested in accelerating your innovation process? Contact us below to find out how CIKONI can assist you:

[wpforms id=”1478″ title=”false” description=”false”]